Cartworth

Settlement in Yorkshire

England

Cartworth

Cartworth is a small village located in the Holme Valley of West Yorkshire, England. Situated approximately 6 miles southeast of Huddersfield, it is nestled amidst the picturesque rolling hills and lush countryside that characterizes the region. With a population of around 500 residents, Cartworth exudes a tranquil and close-knit community atmosphere.

The village is primarily residential, with a scattering of traditional stone-built houses and cottages that showcase the area's rich architectural heritage. These charming properties are often surrounded by well-tended gardens, adding to the overall charm of the village. The idyllic setting of Cartworth offers breathtaking panoramic views of the surrounding countryside, creating a serene and peaceful environment for its inhabitants.

Despite its small size, Cartworth boasts a few amenities to cater to the needs of its residents. A local pub, The Cartworth Arms, serves as a central gathering point for the community, offering a place to relax and socialize. Additionally, there are a handful of small businesses, including a post office and convenience store, ensuring that basic necessities are readily available.

Cartworth is an ideal location for nature enthusiasts, with numerous walking trails and scenic routes in close proximity. The nearby Holme Valley and Peak District National Park provide ample opportunities for outdoor activities such as hiking, cycling, and birdwatching. The village's proximity to Huddersfield also offers residents easy access to a wider range of amenities and services.

In conclusion, Cartworth is a charming and peaceful village that offers its residents a close-knit community, stunning natural surroundings, and a tranquil way of life.

If you have any feedback on the listing, please let us know in the comments section below.

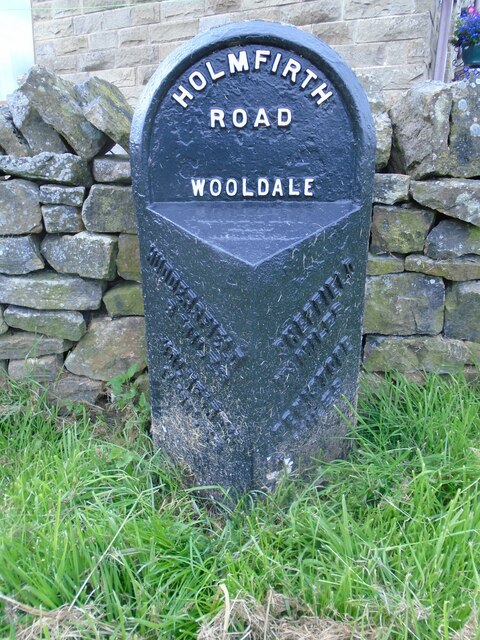

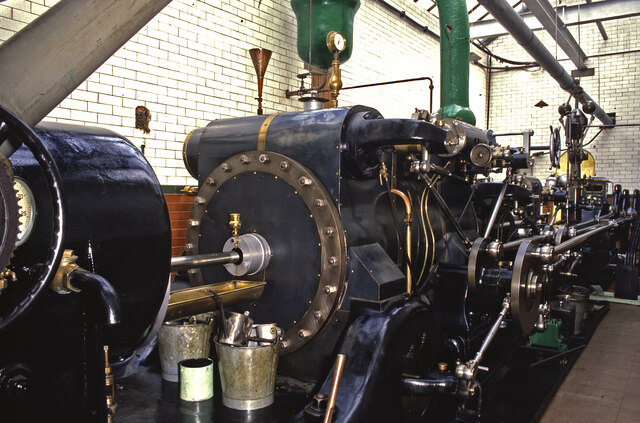

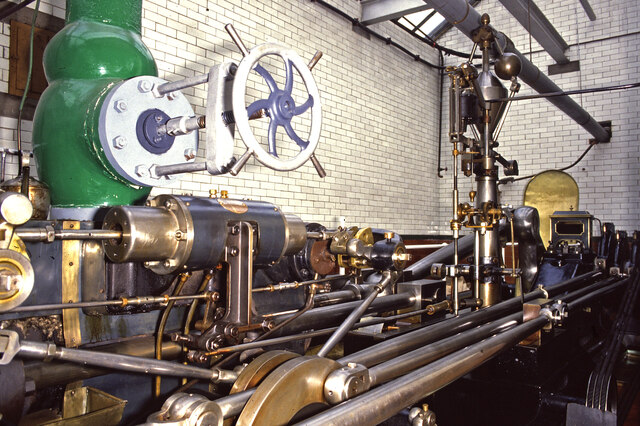

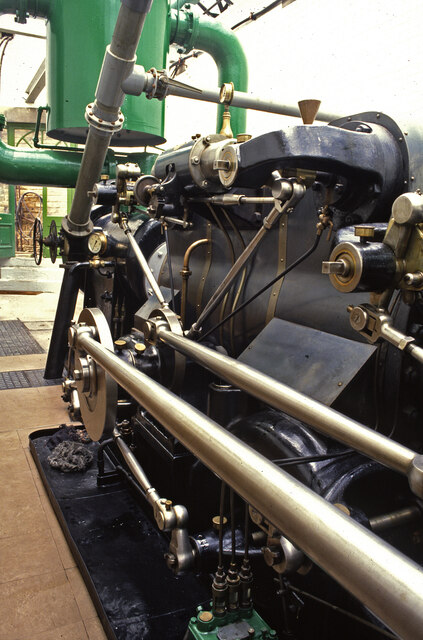

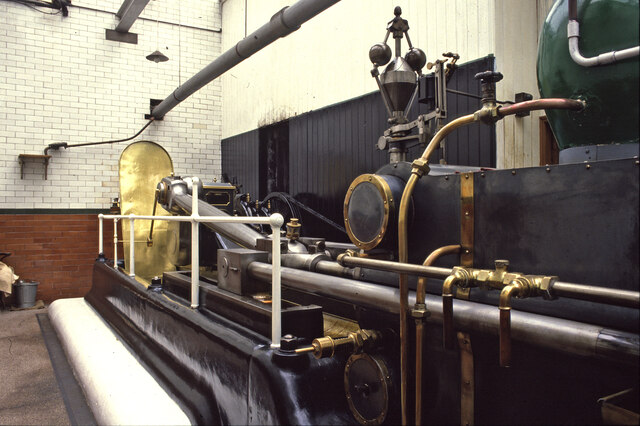

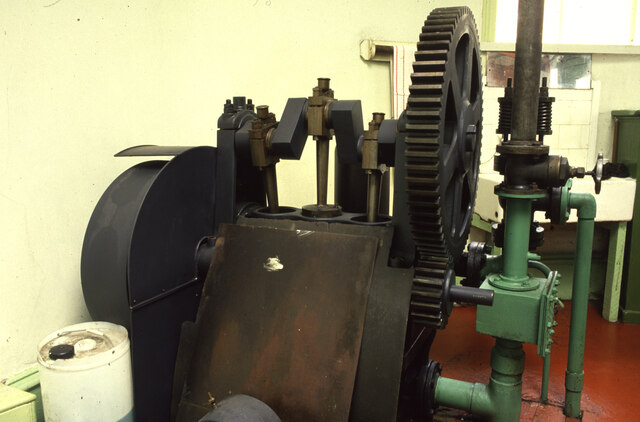

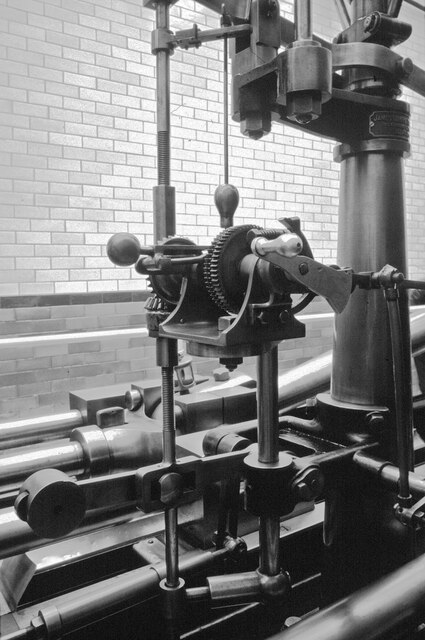

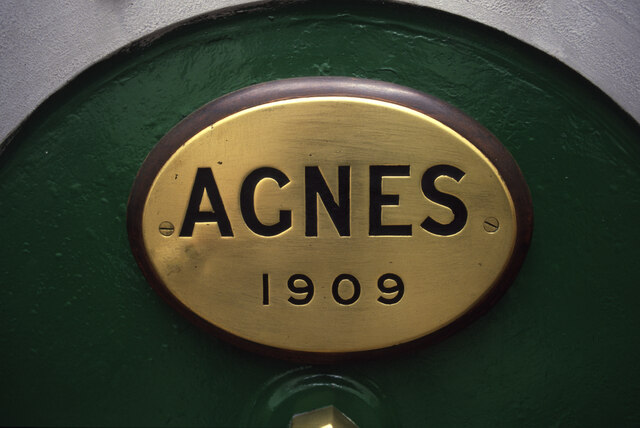

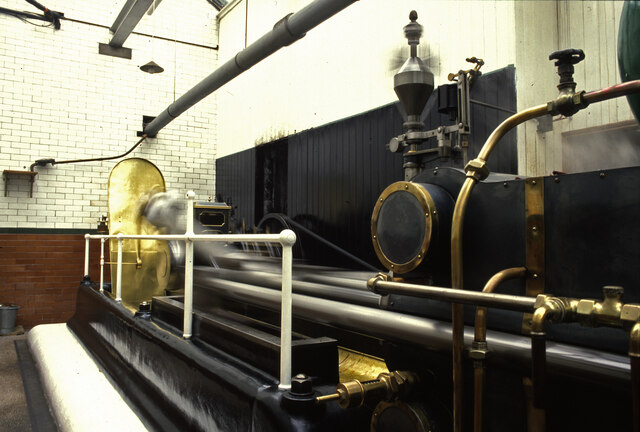

Cartworth Images

Images are sourced within 2km of 53.559875/-1.787858 or Grid Reference SE1407. Thanks to Geograph Open Source API. All images are credited.

Cartworth is located at Grid Ref: SE1407 (Lat: 53.559875, Lng: -1.787858)

Division: West Riding

Unitary Authority: Kirklees

Police Authority: West Yorkshire

What 3 Words

///reception.enhances.crisps. Near Holmfirth, West Yorkshire

Nearby Locations

Related Wikis

Arrunden

Arrunden is a hamlet in the civil parish of Holme Valley, West Yorkshire, England. It is located 1.3 miles (2.1 km) south-southwest of Holmfirth. ��2...

River Ribble, West Yorkshire

The River Ribble is a minor river running through the town of Holmfirth in Kirklees, West Yorkshire, England. Rising at the outflow of Holme Styes Reservoir...

Holmfirth

Holmfirth () is a town in the Metropolitan Borough of Kirklees, West Yorkshire, England. It is located 6 miles (9.7 km) south of Huddersfield and 14 miles...

Lane, West Yorkshire

Lane Village is a small hamlet 3 miles (4.8 km) southwest of Holmfirth and approximately half a mile southwest of Holme Village on the A6024 Woodhead Road...

Holy Trinity Church, Holmfirth

Holy Trinity Church, Holmfirth is an Anglican church in the town of Holmfirth in West Yorkshire, England. Holmfirth's chapelry historically covered townships...

Burnlee

Burnlee is a village in the Holme Valley in Kirklees, West Yorkshire, England. It is bordered by the settlements of Holmfirth, Upperthong and Hinchcliffe...

Holmfirth railway station

Holmfirth railway station is a former railway station that served the town of Holmfirth in West Yorkshire, England. == History == The branch line to Holmfirth...

Moxon Huddersfield

Moxon Huddersfield Ltd is a high-end British textile manufacturer of luxury worsted and woollen suiting fabrics. It is located at Yew Tree Mills, Holmbridge...

Nearby Amenities

Located within 500m of 53.559875,-1.787858Have you been to Cartworth?

Leave your review of Cartworth below (or comments, questions and feedback).