Wild Boar Clough

Valley in Yorkshire

England

Wild Boar Clough

Wild Boar Clough is a picturesque valley located in Yorkshire, England. Nestled within the scenic Peak District National Park, this stunning natural landscape offers visitors a unique and immersive experience in the heart of nature. The valley is characterized by its steep slopes, rugged terrain, and meandering streams.

The name "Wild Boar Clough" is believed to have originated from the presence of wild boar in the area during medieval times. Today, it serves as a reminder of the region's rich history and wildlife diversity. The valley is a popular destination for hikers, nature enthusiasts, and photographers, who are drawn to its unspoiled beauty.

Walking through Wild Boar Clough, visitors can discover an array of flora and fauna. The valley is home to a variety of plant species, including heather, ferns, and mosses, which blanket the landscape in vibrant colors. Wildlife such as deer, foxes, and birds of prey can also be spotted in the area, providing a captivating sight for nature lovers.

The valley is crisscrossed by several walking trails, enabling visitors to explore its hidden gems. The paths wind through dense woodlands, past cascading waterfalls, and alongside babbling brooks. These trails offer breathtaking panoramic views of the surrounding countryside, making it a haven for photographers and those seeking tranquility.

Overall, Wild Boar Clough is a true gem within the Yorkshire countryside. Its untouched beauty, diverse wildlife, and peaceful ambiance make it a must-visit destination for anyone looking to immerse themselves in the natural wonders of the area.

If you have any feedback on the listing, please let us know in the comments section below.

Wild Boar Clough Images

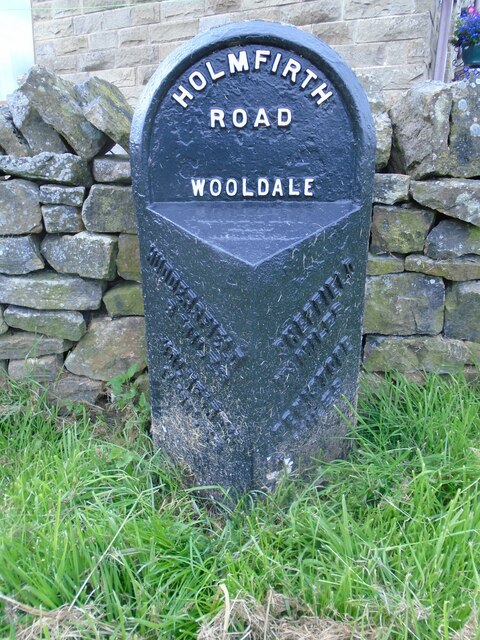

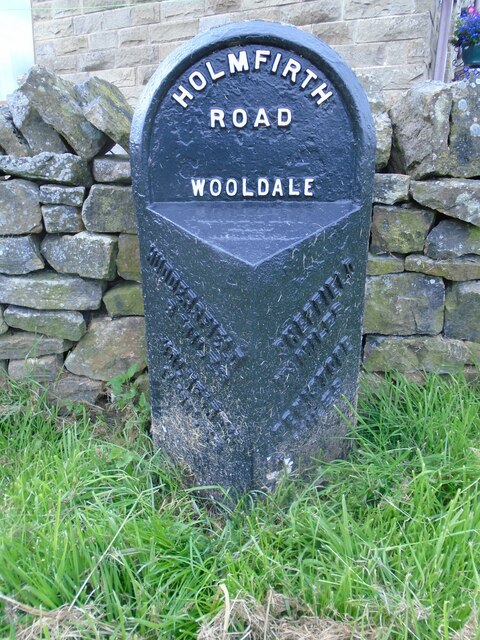

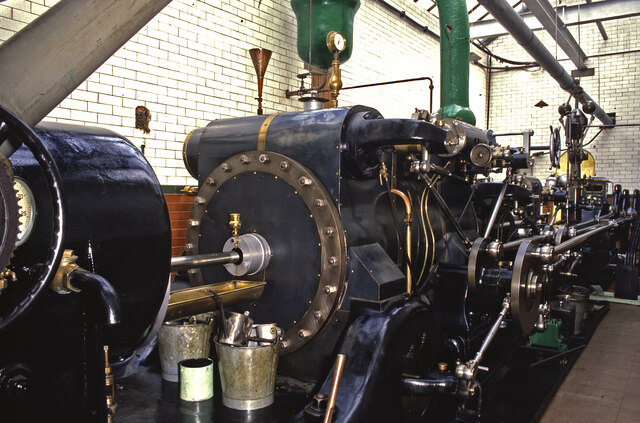

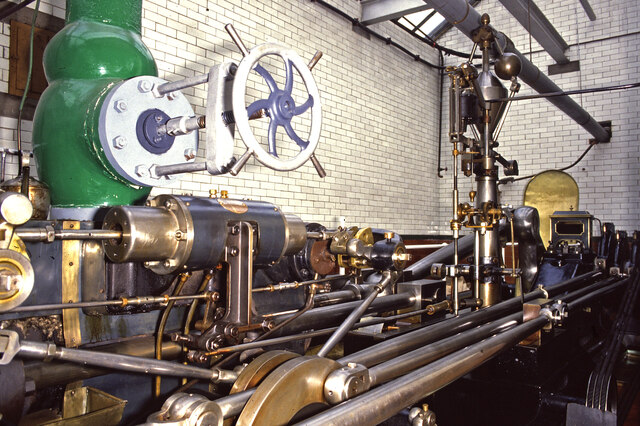

Images are sourced within 2km of 53.545144/-1.7697309 or Grid Reference SE1505. Thanks to Geograph Open Source API. All images are credited.

Wild Boar Clough is located at Grid Ref: SE1505 (Lat: 53.545144, Lng: -1.7697309)

Division: West Riding

Unitary Authority: Kirklees

Police Authority: West Yorkshire

What 3 Words

///blitz.stems.jokers. Near Holmfirth, West Yorkshire

Nearby Locations

Related Wikis

Hade Edge

Hade Edge is a small village to the south of Holmfirth and southeast of Hepworth in West Yorkshire, England. It is in the parish of Holme Valley and the...

Hepworth, West Yorkshire

Hepworth is a village and former civil parish, now in the parish of Holme Valley, in the metropolitan borough of Kirklees, in West Yorkshire, England....

Arrunden

Arrunden is a hamlet in the civil parish of Holme Valley, West Yorkshire, England. It is located 1.3 miles (2.1 km) south-southwest of Holmfirth. ��2...

Barnside

Barnside is a hamlet on Barnside Lane approximately 3/4 mile to the southeast of Hepworth in West Yorkshire, England. It is in the civic parish of Holme...

Nearby Amenities

Located within 500m of 53.545144,-1.7697309Have you been to Wild Boar Clough?

Leave your review of Wild Boar Clough below (or comments, questions and feedback).