Virginia Wood

Wood, Forest in Cornwall

England

Virginia Wood

Virginia Wood is a picturesque woodland area located in Cornwall, England. Covering an expansive area, the wood is known for its abundant natural beauty and diverse wildlife. It is a popular destination for nature enthusiasts, hikers, and photographers alike.

The wood is characterized by its dense vegetation, primarily consisting of oak, beech, and ash trees, creating a lush and vibrant canopy. The forest floor is covered in a carpet of ferns, mosses, and wildflowers, adding to the enchanting atmosphere of the wood. The vibrant colors of the changing leaves during autumn make it a particularly stunning sight.

Several walking trails wind their way through Virginia Wood, allowing visitors to explore its various nooks and crannies. These paths provide opportunities to discover hidden streams, charming bridges, and captivating viewpoints. Along the way, visitors may encounter a variety of wildlife, including deer, foxes, badgers, and numerous bird species.

The wood offers a tranquil and peaceful setting, making it an ideal place for relaxation and contemplation. Nature lovers can enjoy the serene ambiance, listening to the soothing sounds of birdsong and rustling leaves. The wood also provides a habitat for rare and protected species, contributing to its ecological significance.

Virginia Wood is easily accessible, with parking facilities and nearby amenities. It is a gem of Cornwall's natural landscape, offering a unique opportunity to immerse oneself in the beauty of the British countryside.

If you have any feedback on the listing, please let us know in the comments section below.

Virginia Wood Images

Images are sourced within 2km of 50.364864/-4.9035458 or Grid Reference SW9355. Thanks to Geograph Open Source API. All images are credited.

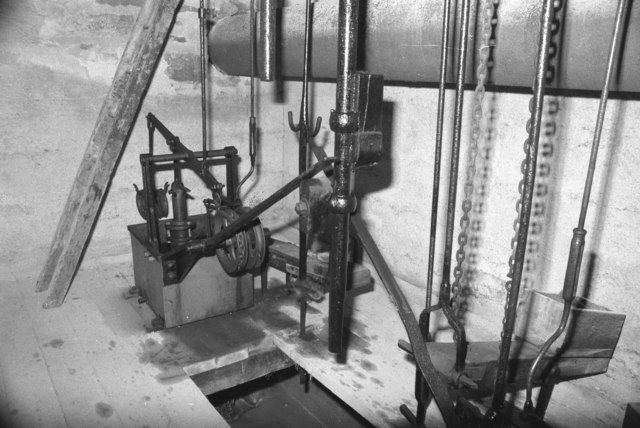

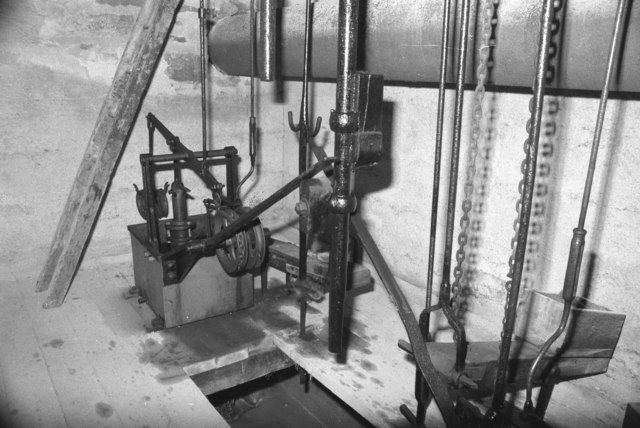

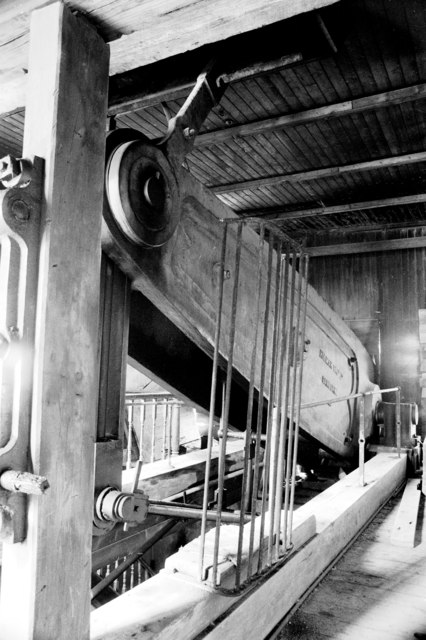

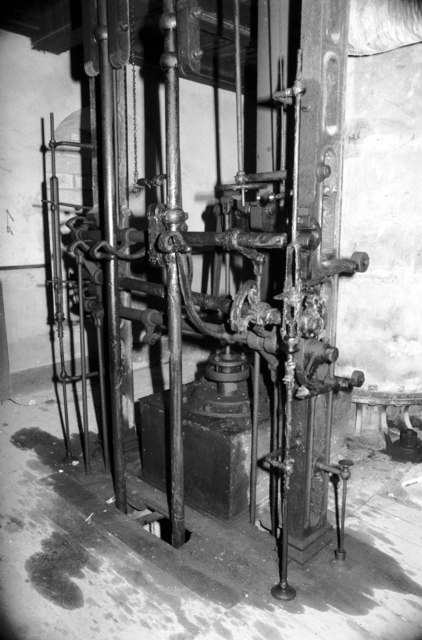

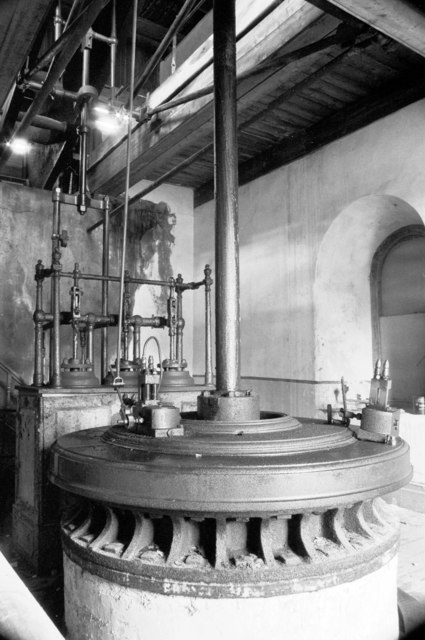

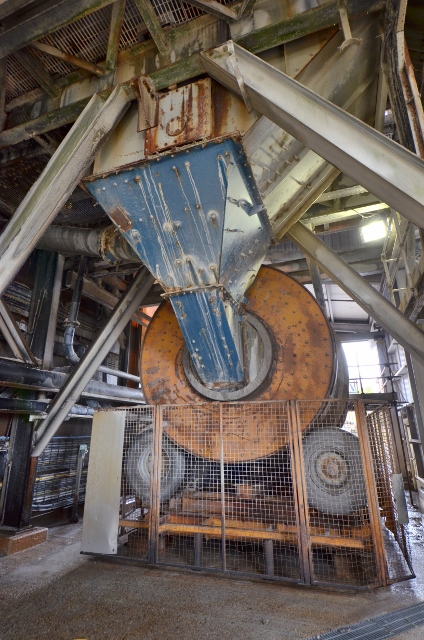

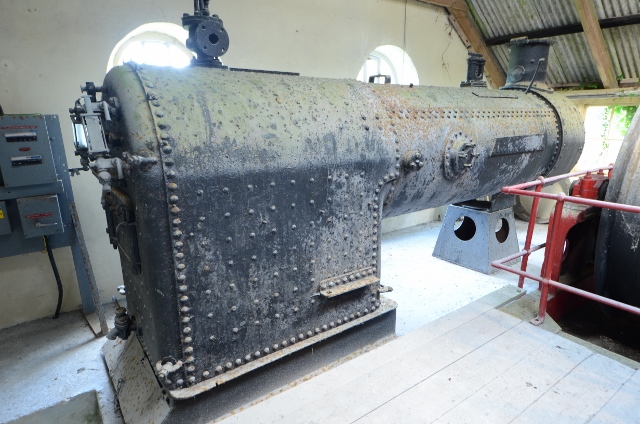

![Parkandillick - Steam Winch A steam winch used for hauling items out of the clay pits. Complete with boiler.

<a href="https://www.geograph.org.uk/photo/3693401">SW9456 : Parkandillick - Boiler</a>] Davey, Paxman of Colchester.](https://s2.geograph.org.uk/geophotos/03/69/34/3693406_5aaf6613.jpg)

Virginia Wood is located at Grid Ref: SW9355 (Lat: 50.364864, Lng: -4.9035458)

Unitary Authority: Cornwall

Police Authority: Devon and Cornwall

What 3 Words

///accented.launch.owner. Near St Stephen, Cornwall

Nearby Locations

Related Wikis

Little Treviscoe

Little Treviscoe is a village near Treviscoe in Cornwall. It contains about 30 properties. There are numerous abandoned china clay workings in the area...

Treviscoe

Treviscoe (Cornish: Trevosker) is a village south of St Dennis in Cornwall, England, United Kingdom. There are large Imerys china clay works nearby....

Bodella

Bodella is a hamlet in mid Cornwall, England, United Kingdom. It is situated half-a-mile southwest of St Dennis in an area of china clay quarries. ��2...

Retew

Retew was a village near St Austell in Cornwall, England, that was mostly demolished in the early 1960s when the nearby Wheal Remfrey china clay quarry...

Have you been to Virginia Wood?

Leave your review of Virginia Wood below (or comments, questions and feedback).