Allicombe Plantation

Wood, Forest in Somerset South Somerset

England

Allicombe Plantation

Allicombe Plantation is a historic woodland located in Somerset, England. Situated near the village of Allicombe, the plantation covers an area of approximately 200 acres. The woodland is predominantly composed of various species of trees, including oak, beech, and ash, creating a diverse and picturesque forest environment.

The plantation has a rich history dating back to the medieval period when it was established as a hunting ground for local nobility. Over the centuries, it has changed ownership several times and was eventually acquired by the Somerset County Council in the early 20th century. Today, it is managed by the council's forestry department, ensuring its preservation and accessibility to the public.

Allicombe Plantation offers visitors a range of recreational activities and amenities. It features a network of well-maintained footpaths and trails, allowing hikers and nature enthusiasts to explore the woodland's beauty. The plantation is also home to an abundance of wildlife, including various bird species, deer, and small mammals, providing ample opportunities for wildlife observation and photography.

In addition to its natural beauty, Allicombe Plantation offers a picnic area and a children's play area, making it a popular destination for families and outdoor gatherings. The site is also regularly used for educational purposes, with schools and environmental groups organizing field trips to learn about the local flora and fauna.

Overall, Allicombe Plantation is a cherished natural asset in Somerset, providing a tranquil escape for visitors to connect with nature and enjoy the beauty of the woodlands.

If you have any feedback on the listing, please let us know in the comments section below.

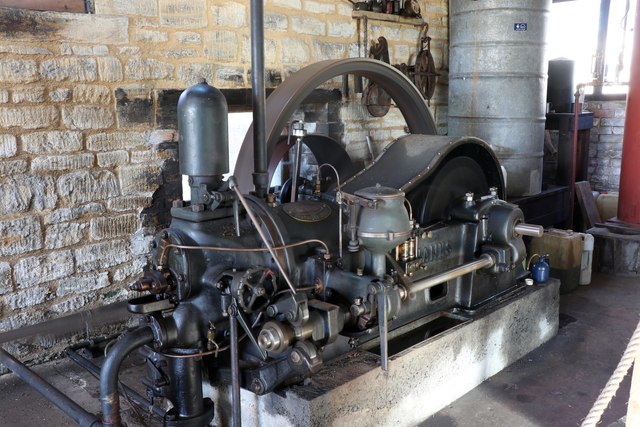

Allicombe Plantation Images

Images are sourced within 2km of 50.92146/-2.7188594 or Grid Reference ST4913. Thanks to Geograph Open Source API. All images are credited.

Allicombe Plantation is located at Grid Ref: ST4913 (Lat: 50.92146, Lng: -2.7188594)

Administrative County: Somerset

District: South Somerset

Police Authority: Avon and Somerset

What 3 Words

///gates.rescue.configure. Near West Coker, Somerset

Nearby Locations

Related Wikis

Nearby Amenities

Located within 500m of 50.92146,-2.7188594Have you been to Allicombe Plantation?

Leave your review of Allicombe Plantation below (or comments, questions and feedback).