St. Dennis

Civil Parish in Cornwall

England

St. Dennis

St. Dennis is a civil parish located in the county of Cornwall, England. Situated in the central part of the county, it lies approximately 7 miles east of the town of St. Austell and 12 miles north of the city of Truro. The parish covers an area of around 4 square miles.

Primarily a rural area, St. Dennis is known for its picturesque landscapes and charming countryside. It is surrounded by rolling hills and farmlands, with the Goss Moor Nature Reserve located to the south of the parish.

The village of St. Dennis serves as the main settlement within the parish. It is a small, close-knit community with a population of around 2,000 people. The village offers a range of amenities, including a primary school, a church, a village hall, and a few local shops and pubs.

Historically, St. Dennis was a mining village, and the remnants of this industry can still be seen today. The village is home to the St. Dennis Band, an acclaimed brass band that has a long-standing tradition and has won numerous awards.

The parish is well-connected to the surrounding areas by road, with the A3058 passing through the village, providing easy access to nearby towns and cities. The stunning coastline of the English Channel is just a short drive away, offering opportunities for outdoor activities and leisurely walks along the beach.

Overall, St. Dennis is a peaceful and picturesque civil parish, offering a rural retreat for its residents and visitors alike.

If you have any feedback on the listing, please let us know in the comments section below.

St. Dennis Images

Images are sourced within 2km of 50.388696/-4.883473 or Grid Reference SW9558. Thanks to Geograph Open Source API. All images are credited.

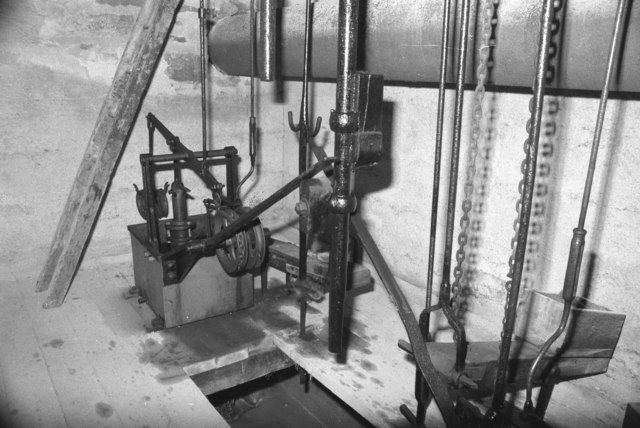

![Parkandillick - Steam Winch A steam winch used for hauling items out of the clay pits. Complete with boiler.

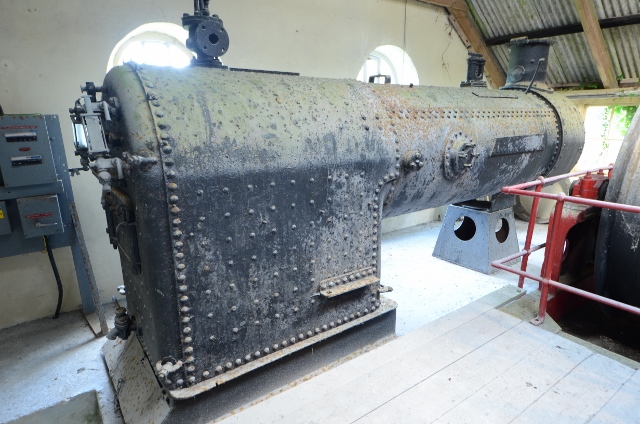

<a href="https://www.geograph.org.uk/photo/3693401">SW9456 : Parkandillick - Boiler</a>] Davey, Paxman of Colchester.](https://s2.geograph.org.uk/geophotos/03/69/34/3693406_5aaf6613.jpg)

St. Dennis is located at Grid Ref: SW9558 (Lat: 50.388696, Lng: -4.883473)

Unitary Authority: Cornwall

Police Authority: Devon & Cornwall

What 3 Words

///consented.correct.manly. Near St Dennis, Cornwall

Nearby Locations

Related Wikis

St Dennis, Cornwall

St Dennis (Cornish: Tredhinas) is a civil parish and village in Cornwall, England, United Kingdom. The village is situated on the B3279 between Newquay...

St Dennis Junction

St Dennis Junction was in St Dennis, Cornwall. == 1849 - 1960 == The history of railway lines through the Cornish village of St. Dennis dates back as far...

St Dennis A.F.C.

St Dennis Association Football Club is a football club based in St Dennis, Cornwall. They are currently members of the South West Peninsula League Premier...

Gothers

Gothers is a hamlet near and northeast of St Dennis (where the 2011 census population was included ) in mid Cornwall, England.The manor of Gothers was...

Nearby Amenities

Located within 500m of 50.388696,-4.883473Have you been to St. Dennis?

Leave your review of St. Dennis below (or comments, questions and feedback).