Bedford Wood

Wood, Forest in Lancashire

England

Bedford Wood

Bedford Wood is a picturesque woodland located in the county of Lancashire, England. Situated near the village of Bedford, this natural area spans over a vast expanse of land, covering approximately 500 acres. The woodland is known for its dense and diverse collection of trees, creating a serene and tranquil atmosphere.

Visitors to Bedford Wood can expect to find a variety of tree species, including oak, beech, birch, and pine. The tall, majestic trees provide a canopy that filters the sunlight, creating a dappled effect on the forest floor. This makes it an ideal habitat for a wide range of flora and fauna.

The woodland is home to a multitude of wildlife, making it a popular spot for nature enthusiasts and birdwatchers. Bird species such as woodpeckers, owls, and various songbirds can be heard singing their melodies throughout the day. Additionally, small mammals like rabbits, squirrels, and hedgehogs can often be spotted scurrying among the undergrowth.

For those looking to explore Bedford Wood, there are several walking trails that wind through the forest. These paths provide visitors with the opportunity to immerse themselves in the natural beauty of the area, while also offering glimpses of the surrounding countryside.

Overall, Bedford Wood is a charming natural space, offering a peaceful retreat from the hustle and bustle of everyday life. Its rich biodiversity and tranquil surroundings make it a must-visit destination for nature lovers and those seeking solace in the beauty of the outdoors.

If you have any feedback on the listing, please let us know in the comments section below.

Bedford Wood Images

Images are sourced within 2km of 53.506704/-2.4973548 or Grid Reference SD6701. Thanks to Geograph Open Source API. All images are credited.

Bedford Wood is located at Grid Ref: SD6701 (Lat: 53.506704, Lng: -2.4973548)

Unitary Authority: Wigan

Police Authority: Greater Manchester

Also known as: Hough Wood

What 3 Words

///excuse.brief.rocket. Near Leigh, Manchester

Nearby Locations

Related Wikis

Bedford Colliery disaster

The Bedford Colliery disaster occurred on Friday 13 August 1886 when an explosion of firedamp caused the death of 38 miners at Bedford No.2 Pit, at Bedford...

Bedford Colliery

Bedford Colliery, also known as Wood End Pit, was a coal mine on the Manchester Coalfield in Bedford, Leigh, Lancashire, England. The colliery was owned...

Atherton Hall, Leigh

Atherton Hall was a country house and estate in Atherton historically a part of Lancashire, England. The hall was built between 1723 and 1742 and demolished...

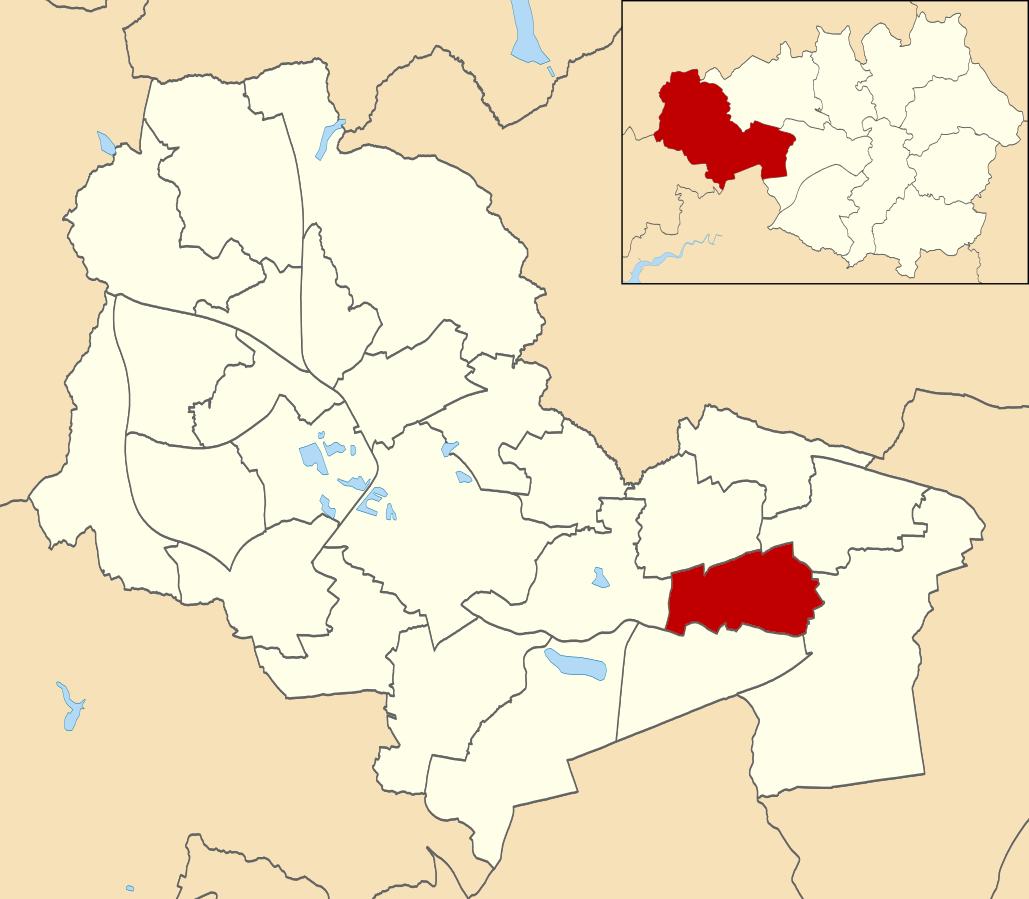

Leigh East (ward)

Leigh East is an electoral ward in Leigh, England. It forms part of Wigan Metropolitan Borough Council, as well as the parliamentary constituency of Leigh...

Nearby Amenities

Located within 500m of 53.506704,-2.4973548Have you been to Bedford Wood?

Leave your review of Bedford Wood below (or comments, questions and feedback).